Revitalizing American Steel: A Bold Turn in U.S. Manufacturing

The American steel industry has experienced a remarkable turnaround over the past few years, and the latest data show that domestic steelmakers are once again on the rise. Following a period marked by tricky parts and tangled issues under previous administrations, the current policies have sparked a resurgence that is positively impacting American manufacturing. This opinion editorial takes a closer look at how protective tariffs and strong leadership have helped breathe new life into the steel industry, while also benefiting the automotive sector and bolstering national security.

In today’s fast-changing global marketplace, the fine points of trade policies can often feel overwhelming—but the shifts in the U.S. steel market under recent presidential leadership are clear. The measures introduced to shield domestic production from unfair foreign competition have not only revitalized manufacturing jobs but have also fueled a growth spurt that benefits several key industries. With American steelmakers like Cleveland-Cliffs, Steel Dynamics, and Nucor posting impressive earnings, it is clear that a coordinated economic strategy aimed at protecting homegrown businesses is working.

Strengthening the Backbone of U.S. Manufacturing with Protective Tariffs

One of the major drivers behind the steel renaissance is the implementation of strong protective tariffs. These tariffs have helped safeguard the domestic market from an influx of substandard imports that were once flooding the market. By making foreign steel less competitive, American manufacturers have found a fertile environment in which to grow. The result has been a rapid resurgence in production, and with it, a revitalization of sectors that rely heavily on high-quality steel, such as automotive and heavy equipment manufacturing.

For many, the adjustments in trade policy might seem intimidating or even nerve-racking at first. However, when you poke around the new policy framework, it becomes evident that these measures are a super important part of protecting the domestic industry. By steering through the complicated pieces of the international trade puzzle, U.S. leaders have managed to secure a future where American workers and manufacturers can thrive once more.

How Tariffs Are Reshaping the Industry

The benefits of protective tariffs extend far beyond just keeping jobs on American soil. They have also contributed to a healthier, more competitive domestic market where companies are driven to innovate and increase efficiency. Industry leaders point out that the tariffs have been especially effective in managing the influx of low-quality imports—a move that in turn has enhanced product standards and strengthened overall supply chain reliability.

- Protection of domestic jobs and manufacturing capacity

- Increased competitiveness for American products in the global market

- Enhanced standards through reduced reliance on lower quality imports

- Boosted confidence in the U.S. manufacturing sector

Revitalizing American Steelmakers: Company Performances Speak Volumes

Several prominent U.S. steel companies have demonstrated the positive impact of these policy changes. For example, Ohio-based Cleveland-Cliffs has reported record steel shipments in the second quarter of 2025. The company’s CEO, Lourenco Goncalves, mentioned that strong governmental support, paired with the right set of tariffs, has played a key role in supporting the domestic automotive and steel industries.

Meanwhile, Indiana-based Steel Dynamics experienced a 39% rise in operating income accompanied by a 19% boost in adjusted EBITDA during the same period. North Carolina’s Nucor is predicting that its second-quarter earnings could quadruple compared to the first quarter. These results collectively underline how effective trade policies can be when they not only protect but also nurture the domestic market. Furthermore, they highlight how essential it is for American industry to have policies that encourage growth and sustainability.

| Company | Key Performance Indicator | Notable Quote/Indicator |

|---|---|---|

| Cleveland-Cliffs | Record steel shipments | “Tariffs have protected domestic jobs and boosted production.” |

| Steel Dynamics | 39% increase in operating income; 19% in EBITDA | “Growth driven by protective measures.” |

| Nucor | Q2 earnings potentially four times Q1 | “Marking a new era for domestic steel production.” |

Tariffs and the Automotive Industry: A Symbiotic Relationship

The resurgence in steel production is not an isolated phenomenon—it is deeply intertwined with broader developments in the automotive sector, which is indispensable to American manufacturing. Automakers, long reliant on a just-in-time model of production that was often undermined by imported materials, are now finding a renewed reliability in domestic steel supplies. When you take a closer look at the synergy between these two industries, it’s evident that the positive effects are mutually reinforcing.

Automotive companies benefit from increased availability of high-grade steel, which is critical for building stronger, safer vehicles. In turn, domestic steelmakers enjoy a steady demand from automakers who are eager to take advantage of products that are now more competitively priced and readily available, thanks to the reduced risk of foreign delays or quality issues.

Key Benefits for the Automotive Sector

The trade restrictions and resulting boost in domestic production have several tangible implications for the automotive industry, including:

- Stable Supply Chains: Reliable domestic production reduces delays and ensures that automakers can stick to their production schedules without worrying about foreign market disruptions.

- Enhanced Quality Control: With tariffs curbing substandard imports, automakers now have better access to high-quality raw materials, which translates into safer and longer-lasting vehicles.

- Job Creation: Both the steel and automotive sectors are creating more jobs, which in turn stimulates local economies and builds stronger communities.

- Increased Investment: As markets stabilize, increased investor confidence in the automotive sector emerges, fostering additional innovations and long-term growth.

President Trump’s Role in Steering Through the Confusing Bits of Trade Policy

One cannot overlook the role of leadership in this major turnaround. It is not common to see such a direct connection between government policy and industry performance. Under the current administration, decisive actions have been taken to protect and promote American manufacturing. The notion of a “Golden Share” in companies like Pittsburgh-based U.S. Steel represents a proactive approach to safeguarding national interests. This strategic move not only shields jobs from being outsourced but also ensures that critical industries remain in capable American hands.

While some critics argue that such measures isolate American businesses from global competition, a closer examination suggests that these policies are designed with long-term sustainability in mind. The idea is to create an environment where domestic industries can build up their capacity and quality standards to meet, and eventually surpass, global benchmarks. In other words, by getting into the nitty-gritty of trade regulations, the current administration is setting the stage for sustainable growth.

Presidential Initiatives: A Look at the Protective Measures

Here’s a breakdown of some of the key initiatives that have contributed to the recent upsurge in the steel industry:

- Implementation of robust tariffs to level the playing field for domestic companies.

- Adoption of policies aimed at protecting national security by ensuring a stable supply of critical materials.

- Promotion of a “Golden Share” strategy that prevents the loss of pivotal domestic assets.

- Encouragement of reinvestment into American manufacturing facilities through tax incentives and other supportive measures.

Boosting National Security and Workforce Confidence

Beyond the improved financial performance of steel companies, the recovery of the domestic steel industry carries significant implications for national security. Steel is among the most essential materials used in defense infrastructure and other critical applications. By bolstering domestic production, the United States is ensuring that it is not overly reliant on potentially unreliable or hostile foreign suppliers. This move represents a strategic investment in the country’s long-term safety and operational independence.

Additionally, protecting American jobs is a super important aspect of these policies. The steel industry, once heavily plagued by job losses due to international competition, is now seeing a renewed sense of optimism among workers and community leaders alike. When communities see that local manufacturers are thriving, it creates a ripple effect—boosting morale, encouraging further investment, and ultimately fostering a stronger, more resilient economy.

How Workforce Revitalization Impacts the Economy

The workforce benefits from these policies in several notable ways:

- Job Security: With domestic production on the rise, job losses are decreasing while new opportunities are emerging.

- Community Investment: Improved corporate profits mean more investments in local facilities and infrastructure.

- Skill Enhancement: Workers gain access to training programs and advanced machinery, which leads to higher overall productivity.

- Economic Multiplier Effect: Increased wages and job stability in the steel industry benefit local economies and support associated service sectors.

Taking a Closer Look: Small Business and Industrial Manufacturing Benefits

While the headlines often focus on major corporations, it’s important to acknowledge that small businesses and local industrial manufacturers are also reaping the rewards of these protective trade measures. Many smaller operations have been struggling to get around the nerve-racking twists and turns of global supply chains. The renewed focus on domestic production has provided these businesses with easier access to reliable, high-quality steel and related materials, thereby leveling the playing field with larger competitors.

This renewed focus on domestic sourcing has had a cascading effect. Small manufacturing businesses that rely on steel for everything from construction to specialized equipment are better positioned to compete in both domestic and international markets. In many cases, local businesses are now more agile and capable of adapting to rapidly changing economic climates, ensuring that the benefits of the broader industrial resurgence are felt at every level of the economy.

Key Benefits for Small Businesses and Local Manufacturers

There are several subtle details in the way protective tariffs benefit small businesses:

- Cost-Effective Sourcing: With domestic prices stabilizing, small businesses find it easier to budget and maintain cost-effective operations.

- Reliable Supply: A resurgent domestic steel industry means fewer production delays, allowing small manufacturers to meet tight deadlines.

- Enhanced Local Partnerships: Small businesses are forming strategic alliances with domestic suppliers, ensuring better integration across regional supply networks.

- Increased Investment Opportunities: Local manufacturers are more likely to receive funding or grow organically when supported by favorable domestic production trends.

Digging Into the Broader Implications: A National Economic Perspective

At its core, the resurgence in the steel industry is a reflection of a larger narrative: American resilience in the face of global challenges. The protective measures that have been implemented are not just about keeping jobs and safeguarding the domestic market; they speak to a broader strategy of ensuring economic independence and sustainability. By nurturing homegrown industries, policymakers are essentially investing in a future where American manufacturing does not crumble under the weight of confusing international market forces.

This reorientation towards domestic strength is both a practical and strategic move. It presents opportunities for future investments in innovation, infrastructure, and workforce development—all of which are key to maintaining America’s competitive edge. Moreover, having a robust domestic steel industry means that the United States can respond more nimbly to global disruptions, be they economic slowdowns or geopolitical crises.

Long-Term Implications for the National Economy

To better understand the national scope of these developments, consider the following points:

- Enhanced Global Competitiveness: With protective tariffs in place, American steel products are now better positioned to compete overseas, potentially boosting exports.

- Sustainable Growth Model: The focus on quality and reliability in domestic production creates a model that is less vulnerable to external shocks.

- Resilient Supply Chains: Reducing reliance on international imports ensures that critical industries are less likely to be affected by global market fluctuations.

- Innovation and Technological Advancements: As companies invest in new technologies to boost efficiency, the entire manufacturing sector stands to benefit.

Challenges and the Road Ahead: Steering Through the Nitty-Gritty of Economic Policy

Even as optimism grows, it is essential to acknowledge that the journey toward a fully revitalized domestic steel industry is not without its twists and turns. Transitioning from a market heavily influenced by low-cost imports to one that values domestic production involves working through complicated pieces of policy, economic shifts, and global market dynamics. Critics may argue that the current protectionist measures introduce their own set of challenges, such as increasing costs for downstream industries or potential retaliatory measures from trade partners.

Nonetheless, it is important to look at the broader picture. While these policies may appear intimidating or even nerve-racking in the short term, the long-term benefits—ranging from improved job security to enhanced national security—are expected to outweigh the temporary disruptions. The key lies in making strategic adjustments and ensuring that these measures are part of a broader, well-coordinated economic strategy.

Coping with the Uncertainties

In order to successfully manage the path forward, several strategies can be implemented:

- Incremental Policy Adjustments: Gradual changes can help industries adapt without facing abrupt disruptions.

- Industry Collaboration: Regular dialogue between policymakers and industry leaders can help fine-tune policies to address the small distinctions and subtle details that impact the sector.

- Investment in Workforce Training: Equipping workers with the skills needed to operate modern machinery is a key part of maintaining competitiveness.

- Enhanced International Negotiations: While protecting domestic industries, it is also important to seek balanced trade agreements that minimize the risk of retaliation.

Learning from the Past: The Evolution of U.S. Steel and Trade Policies

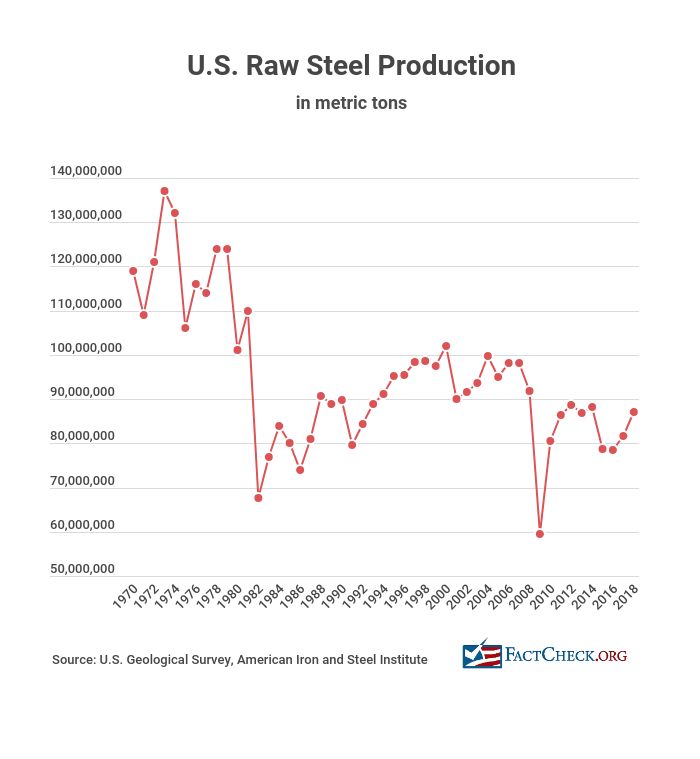

Historically, the American steel industry has faced many daunting challenges—each a lesson in how to manage economic shifts and endure periods loaded with issues. The fluctuations in steel production during the late 20th century and early 2000s, for example, taught policymakers the importance of safeguarding key industrial sectors from the negative impacts of globalization. By taking a closer look at these lessons, the current administration has been able to tailor its approach to better support the domestic market.

The evolution of these policies illustrates a pragmatic approach to problem-solving: rather than diving into radical reforms overnight, incremental measures were introduced to address the most pressing needs of industry stakeholders first. This careful balancing act has helped build the confidence required to drive long-term investments in technology, infrastructure, and workforce development.

Key Lessons from Historical Trade Policies

A quick review of past initiatives highlights some of the strategies that proved successful:

- Support Through Transition Periods: Temporary measures, such as provisional tariffs and subsidies, helped companies adjust to changing market conditions.

- Encouraging Innovation: Periods of protection often spurred investments in new technologies and process improvements.

- Fostering Local Competitiveness: Regional investments and support for smaller manufacturers fostered a more resilient national industry.

- Balanced Trade Relations: Even when protective measures were put in place, efforts to maintain balanced trade relationships helped avoid severe disruptions.

A Future of Opportunities and Remaining Hurdles

As we look ahead, it is important to consider not just the gains, but also the challenges that lie on the road to a fully resilient and competitive U.S. steel industry. While the resurgence of domestic steel production is a clear win for American manufacturing, there are several areas that still require careful thought and attention:

- Adapting to Global Market Dynamics: Even with protective measures, global market trends and economic cycles will continue to impact domestic production. Maintaining flexibility in policy will be key.

- Balancing Costs with Quality: While tariffs have helped stabilize domestic prices, there is a need to ensure that cost increases do not inhibit downstream industries.

- Mitigating Retaliatory Risks: As trade partners react to new tariffs, diplomatic channels must be actively maintained to resolve disputes and foster mutual understanding.

- Investing in Future Technologies: The steel industry must continue to innovate, adopting new technologies that improve efficiency and product quality.

It is clear that the successes of today are built upon a foundation of strategic risk-taking and decisive leadership. As American steelmakers continue to find their footing in an increasingly competitive global arena, the lessons learned from the past serve as guiding principles for a future where the nuances of international trade and domestic production find a balanced harmony.

What Lies Ahead for Policy Makers

Policy makers now face the task of building upon recent successes while anticipating the next set of challenges. Some key areas for future focus include:

- Continuous Improvement in Trade Policies: Refining tariffs and other protective measures to adapt to changing market conditions while minimizing adverse effects on affiliated sectors.

- Strengthening Local Collaborations: Fostering relationships between small businesses, local manufacturers, and large corporations to create a cohesive, resilient manufacturing ecosystem.

- Enhancing Workforce Training Programs: Investing in educational initiatives that prepare workers for the evolving demands of modern manufacturing technology.

- Pursuing Balanced International Agreements: Maintaining open channels for negotiations that protect domestic interests while remaining sensitive to the global economic landscape.

The Synergistic Impact of Leadership, Policy, and Industry Efforts

In summary, the recent turnaround in American steel production is a testament to the power of well-crafted policies combined with strong leadership and dedicated industry effort. By getting into the tangled issues of international competition and domestic market needs, the current administration has set in motion a series of changes that not only revive the steel industry but create broader benefits for sectors like automotive manufacturing and small businesses across the country.

The interplay between government initiatives and private sector agility is evident in the robust performance figures of Cleveland-Cliffs, Steel Dynamics, and Nucor. These companies illustrate how policy-driven market adjustments can encourage industrial growth while protecting jobs and enhancing national security.

While the challenges ahead remain—ranging from global market fluctuations to the need for continuous investments in innovation—the progress made so far is encouraging. By working through the small distinctions and subtle details of economic policy, American leaders are proving that a balanced approach, one that considers both domestic priorities and international realities, is not only possible but necessary for sustainable growth.

Looking Forward: A Roadmap for Continued Success

For those in the industry and policymakers alike, key takeaways for ensuring continued success include:

- Stay Adaptable: Constantly assess and adjust policies to keep pace with global market trends.

- Invest in Workforce and Technology: Enhance training programs and invest in machinery and innovation that boost production.

- Strengthen Industry Collaboration: Create platforms for dialogue among stakeholders to share best practices and troubleshoot emerging issues.

- Prioritize National Interests: Above all, ensure that strategies reinforce the domestic economy, safeguard jobs, and secure critical infrastructure.

Final Thoughts: The Resurgence of American Steel in a Changing Global Landscape

As the U.S. steel industry surges forward under a regime committed to protecting domestic jobs and fostering manufacturing excellence, the broader economic landscape is also evolving. The mechanisms that have reignited a once-struggling industry—protective tariffs, proactive presidential policies, and dedicated efforts by key regional players—illustrate a powerful model of sustainable growth and national resilience.

This remarkable transformation should serve as a wake-up call to industries and policymakers across the country. By carefully managing the confusing bits of international trade and making strategic adjustments to benefit homegrown businesses, the U.S. is not merely reacting to global pressures—it is charting its own course toward a future filled with opportunity, innovation, and economic strength.

Ultimately, the story of American steel today is one of renewal and cautious optimism. It is about finding your way through the tangled issues of modern trade, getting into the fine points of policy reform, and ensuring that every hard-working American has a stake in the nation’s success. With continued commitment and careful management, the steel industry’s revival could very well be a cornerstone for broader industrial progress, setting the stage for a new era of domestic excellence.

In conclusion, the thriving performance of American steel is more than just a series of encouraging statistics—it is a reflection of a fundamentally transformed approach to national economic policy. One that balances the immediate needs of workers and companies with the long-term goals of innovation and global competitiveness. As the nation looks towards the year 2025 and beyond, this balanced approach will remain a must-have ingredient in the recipe for a strong and secure American manufacturing sector.

Originally Post From https://www.kboi.com/2025/07/22/american-steelmakers-are-thriving-under-president-trump/

Read more about this topic at

President Donald J. Trump Restores Section 232 Tariffs

The Trump administration just doubled the tariffs on steel …