Introducing the New Digital Frontier for Refractory Metal Powders

The recent launch of Elmet Technologies’ fully optimised website marks a turning point in the way manufacturers, researchers, and end-users are approaching refractory metal powders. With an emphasis on high-performance materials, the platform is designed to help industry professionals figure a path through the tangled issues of product data, application specifics, and integrated production solutions. This step toward digitisation is not only a move to update product information but also an effort to bring clarity to a sector loaded with tricky parts and confusing bits.

At its core, the digital upgrade offers far more than the typical online brochure. It provides in-depth details—from data sheets and technical specifications for molybdenum, tungsten, niobium, to powders for Additive Manufacturing (AM)—to help customers compare different powder types in pure and alloyed forms. In an age when businesses across industrial manufacturing, automotive, and electric vehicles are seeking better ways to increase production efficiency, platforms like this become an essential resource for staying competitive and informed.

With the demand for faster, more reliable production methods increasing, digitally driven solutions such as this new website give stakeholders the ability to figure a path through the tricky parts of product selection and integration. As companies refine their processes from laboratory dabbling to high-volume automated manufacturing, the ability to quickly find critical information is super important.

Modernizing High-Performance Materials: The Digital Advantage

The move toward an online platform dedicated to refractory metal powders highlights a broader trend in modern digital innovation. Traditional catalogs and scattered data sources can be nerve-racking and overwhelming for professionals trying to keep up with the latest material technologies. The new website offers a streamlined interface that transforms complicated pieces of raw information into an accessible resource. It is designed to help industry experts, from seasoned metallurgists to budding engineers, steer through the hidden complexities of material data.

One of the key advantages of this digital approach is its focus on side-by-side comparisons of product details. The website allows users to dig into the fine points of each powder, such as purity levels, processing capabilities, material properties, and thermal spray applications. Instead of sorting through multiple sites for answers, professionals now have a single repository that addresses these subtle details in a clear and structured format.

In today’s fast-paced business environment, having a tool that can quickly generate a comprehensive overview means that companies can better strategize and plan their manufacturing processes. This digital solution is particularly useful in sectors where small business owners and large manufacturing plants face nerve-racking decisions daily regarding material selection and process integration.

Breaking Down the Website’s Offerings: A Detailed Look

Getting Around Product Specifications and Data Sheets

The new digital platform from Elmet Technologies offers an expanded look at product specifications through clear data sheets and technical documents. Instead of relying on outdated paper catalogs that offer a one-way flow of information, the website enables users to poke around active, instantly updated documents that reflect the latest changes in product data.

Key elements include:

- Detailed technical specifications for different refractory metal powders

- Comparative tables that list subtle differences between pure and alloyed products

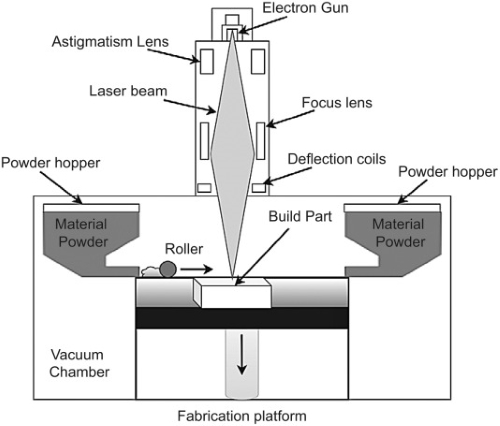

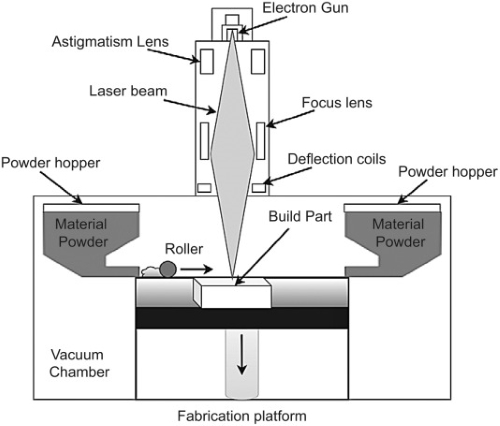

- High-quality images and diagrams to illustrate how powders are processed

- Downloadable PDFs for easy reference both online and offline

These elements together provide a comprehensive guide that helps users get into the nitty-gritty of the product details without the distracting multitude of unrelated information. Instead, everything is laid out in a way where even the small distinctions between products become clear to decision-makers.

Diving Into Pure and Alloyed Powder Options

One of the most exciting aspects of the website is the section dedicated to comparing powder types. Users can take a closer look at the options available for both pure and alloyed powders. This section not only displays the chemical and physical properties of these materials but also provides insights into the tailored applications for each variety.

The website breaks down the following points for each powder category:

- Purity Levels: Information on chemical composition and overall purity, which is key when you need to find your way through the code of manufacturing demands.

- Processing Capabilities: Data concerning the processing methods suitable for each powder—be it spray drying, plasma densification, or spheroidization.

- Material Properties: In-depth details on the thermal, mechanical, and chemical properties that influence performance, ensuring that even the overloaded details are easy to sort out.

- Application Specifics: Insights into which industries have successfully integrated these powders, along with case studies and use scenarios.

This comprehensive breakdown provides a one-stop resource for professionals looking to tackle the tangled pieces of information that come with material selection and ensures that every fine detail is considered before making a sizeable investment.

Understanding Applications Across Industries

Beyond the product specifications, the website shines when it comes to showcasing the practical applications of refractory metal powders. With industries such as chemical processing, high-temperature engineering, electronics, and propulsion in full swing, having an immediate resource that consolidates various use cases is key.

For example, consider the following industry applications featured on the platform:

- Chemical Processing Equipment: Powders used in reactors or other chemical processing machines, where precision and durability are non-negotiable.

- High-Temperature Processing: Refractory powders that maintain integrity even when subjected to extreme heat—a must-have for aerospace and energy production.

- Electronics and Propulsion: Advanced materials in electric vehicles or sophisticated propulsion systems, showing how metal powders can be utilised to enhance performance in a variety of ways.

- X-ray Generation and Thermal Spray Applications: Innovative adaptations that point to the evolving uses of these materials in modern technology.

By listing these diverse applications, the platform removes the intimidating gap between theoretical product details and real-world applications. It provides a roadmap for small business owners and large industrial manufacturers alike to see where these powders can be integrated to boost efficiency and product performance.

Integrating Powder Metallurgy Capabilities with Advanced AM Processes

The Benefits of an Integrated Supply Chain

Elmet Technologies’ comprehensive website is more than just a product catalogue; it is a window into their fully integrated manufacturing process. This approach covers everything from the initial powder reduction and blending steps to advanced machining and Additive Manufacturing. By offering these detailed insights, the platform empowers customers to work through the entire production chain with confidence.

Some key benefits of an integrated approach include:

- Streamlined Production: When all stages—from powder production to high-performance part manufacturing—are linked, the need for external coordination is significantly reduced.

- Cost Efficiency: An integrated system often leads to lower production costs and higher quality control, which can translate into more competitive pricing for end-users.

- Reliability Through Consistency: A fully integrated manufacturing process ensures that the materials produced maintain a consistent quality, making it easier for manufacturers to plan for and control production outcomes.

This kind of detailed, step-by-step information is especially useful for businesses looking to dive in into the world of advanced manufacturing without getting bogged down by the nerve-racking details of miscommunication or gaps in data. In addition, it allows companies to better predict and manage the unpredictable twists and turns inherent in powder metallurgy and AM processes.

Challenges and Hidden Complexities in Refractory Powder Production

Despite the many advantages, the field of refractory metal powders remains full of problems that can frustrate even the most experienced professionals. The detailed breakdown provided on the website helps to demystify many of the confusing bits associated with production. For instance, common challenges include:

- Powder Reduction and Blending: Understanding the subtle parts of chemical reactions and mixing protocols can be tricky and often require careful monitoring.

- Alloy Development: Developing mixtures to achieve specific mechanical and thermal properties involves testing various compositions—a process that can be both nerve-racking and time-consuming.

- Processing Techniques: Procedures such as spray drying or plasma densification come with their own set of complicated pieces that require a very precise set of controls to ensure quality and consistency.

To help address these tangled issues, the digital platform provides detailed illustrations, video tutorials, and real-time updates on production protocols. This wealth of information is designed to assist professionals in making informed decisions and streamlining their manufacturing processes—even when the steps are loaded with confusing bits.

A Closer Look at Additive Manufacturing and Its Future Role

How Digital Platforms Are Revolutionizing Metal 3D Printing

Additive Manufacturing (AM) has evolved from a niche technology into a mainstream manufacturing method, thanks in part to the development of sophisticated digital platforms. The new website not only highlights refractory metal powders but also lays the groundwork for a broader discussion about the role of AM in modern production. By offering detailed product data and real-time updates on production processes, the platform is making it easier for professionals to steer through the nerve-racking process of integrating new technologies into existing production lines.

The revolution in metal 3D printing is marked by several significant changes:

- Enhanced Accessibility to Detailed Materials Data: As companies continue to adopt AM technologies, having immediate access to critical information can be the difference between success and missed opportunities.

- Streamlined Communication Between Suppliers and Manufacturers: An integrated platform ensures that both ends of the supply chain are on the same page, reducing the risk of miscommunication during production.

- Faster Iteration and Prototyping: By providing updated data on material properties and processing capabilities, digital platforms speed up the design and testing processes necessary for effective AM implementation.

In essence, this digital transformation is about doing more with less—less time spent on coordination, less ambiguity in material performance, and less of the overwhelming guesswork that can sometimes plague even established manufacturing teams.

Opportunities in Collaborative Innovation

One of the most promising aspects of platforms like the one introduced by Elmet Technologies is the potential for collaborative innovation. By bringing together detailed, accessible information on material specifications, processing steps, and real-world applications, the platform serves as a meeting ground for industry experts, researchers, and even small business owners looking to dive in and explore new methods of production.

Some of the key collaborative opportunities include:

- Joint Research and Development Initiatives: With transparent data available, companies can more easily partner up to develop improved alloys and processing techniques.

- Training and Knowledge Sharing: The website includes resources such as webinars, detailed tutorials, and case studies that help demystify the fine points of metal powder production and AM.

- Cross-Sector Partnerships: Industries as diverse as aerospace, automotive, and energy are proving that there is immense potential in combining expertise from different fields. This integrated approach reduces the nerve-racking aspects of going it alone and allows for a more rounded, robust product offering.

Collaboration is a key driver of innovation in any modern industry, and the digital transformation represented here serves to create an environment where these partnerships can flourish. This is particularly important for businesses facing the overwhelming challenge of bridging the gap between traditional manufacturing and state-of-the-art technologies.

The Role of Digital Platforms in Industrial Manufacturing and Beyond

Finding Your Way Through the Digital Manufacturing Maze

For companies operating in industrial manufacturing, the road to embracing new technologies can often be a nerve-racking journey filled with tricky parts and unpredictable twists and turns. The new online portal put forth by Elmet Technologies exemplifies how digital tools can simplify this journey. By centralising key data—from product specifications to in-depth application cases—the platform makes it easier for manufacturers to find their way through the tangled issues of modern production challenges.

Key benefits of digitally driven manufacturing solutions include:

- Improved Operational Efficiency: Integrated production data reduces the need for multiple communication channels, leading to smoother operations.

- Enhanced Decision Making: When critical technical details are available at a glance, making informed decisions becomes less intimidating and more straightforward.

- Greater Flexibility and Adaptability: In a world where market demands can change on a dime, having easily accessible production information means companies are better equipped to steer through rapid industry shifts.

The adoption of platforms that combine detailed technical data with a user-friendly interface is a super important step for any business looking to modernize their operations. This trend is particularly relevant in fields such as automotive and electric vehicles, where the efficient use of materials and rapid prototyping are crucial for staying ahead in a competitive market.

Impact on Market Trends and Business Tax Laws

The clear presentation of sophisticated production data not only helps in streamlining manufacturing processes but can also influence broader market trends. As businesses become more digitally inclined and technology-driven, they find themselves better positioned to respond to evolving business tax laws and regulatory changes. Simplified access to detailed product data can lend transparency to costs and efficiencies in production—factors that can ultimately influence tax incentives and governmental support for innovation.

For instance, digital platforms such as this can provide:

- A clearer breakdown of cost elements associated with each production phase

- Real-time data tracking that supports claims for tax credits in research and development activities

- Enhanced reporting capabilities that align with stringent regulatory requirements

By integrating these features, the platform stands as an example of how digital transformation can extend its benefits beyond just production efficiency—impacting everything from market analysis to compliance with business tax laws.

Concluding Thoughts on the Road Ahead

In an industry that is full of problems and overwhelming amounts of data, the launch of a fully optimised website by Elmet Technologies is a breath of fresh air. It takes a modern approach to a longstanding manufacturing challenge by bringing together all the key elements of refractory metal powder data, processing techniques, and application examples onto one easy-to-use digital platform.

This move is emblematic of the larger push toward integrated, digitally managed production environments. Whether you are a small business owner in the manufacturing sector or a large-scale industrial producer, the ability to get around complicated pieces of information and figure a path through the nerve-racking parts of production has never been more critical. The platform’s clear, data-driven layout helps simplify everything from technical specifications to the fine shades that differentiate one material from another.

Moreover, by opening up avenues for collaborative innovation, the digital resources provided help industries not only to sort out production difficulties but also to embrace new opportunities in Additive Manufacturing. They create a space where research and development, combined with transparent and accessible data, can lead to groundbreaking advancements in how we produce everything from high-temperature processing components to state-of-the-art electronic parts.

As we look to the future of metal 3D printing and integrated manufacturing systems, one thing is clear: platforms that help industry professionals dig into the nitty-gritty of production and product specifics are not just a fancy addition—they are a must-have in the digital age. By addressing the little details and offering a comprehensive guide to both the tactical and strategic sides of metal powder production, Elmet Technologies is helping to revolutionize a field that is as critical as it is complex.

This digital transformation has the potential to influence market trends across the board, from industrial manufacturing to automotive and electric vehicles. The clarity and accessibility of data provided can help all stakeholders make better, faster decisions—thus forging a path that is less intimidating and more promising for the future of advanced manufacturing.

In summary, the integration of high-performance refractory metal powders into a comprehensive digital platform represents a significant leap forward for the entire industry. It is a move that not only simplifies previously overwhelming data streams but also lays a solid foundation for future innovation, enhanced collaboration, and improved efficiency. As we continue to manually sort out production challenges and figure a path through the tangled issues of modern manufacturing, tools like this will undoubtedly play a super important role in streamlining processes, reducing costs, and driving progress forward.

Ultimately, the digital platform introduced by Elmet Technologies is indicative of a positive shift. It shows that when businesses take the extra step to make information more accessible, the result is not just an improved workflow but also a more informed, agile industry. With data that is easier to navigate and decisions that are simpler to manage, the future of refractory metal powder production—and by extension, advanced manufacturing—is looking increasingly bright.

This digital revolution is a call to action for those operating in and around the realms of metal 3D printing to embrace technology as a partner in progress. By adopting these digital tools, industry professionals can expect to see fewer of the intimidating obstacles that once hindered innovation and more of the empowering resources that will shape the next generation of manufacturing excellence.

In reflecting on the impact of this new platform, it is clear that whether you are trying to master the tangled issues of powder metallurgy or seeking to integrate efficient Additive Manufacturing techniques, the road ahead is paved with opportunities. This isn’t just about a new website—it’s about a new way of thinking that values accessible, transparent information and collaborative progress as the keys to unlocking a more efficient, innovative future for all sectors of advanced manufacturing.

Originally Post From https://www.metal-am.com/elmet-site-optimised-for-high-performance-refractory-metal-powders/

Read more about this topic at

Advanced Materials | Amaero Inc | TN

Engineer’s Guide to Refractory Metal Powders